- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

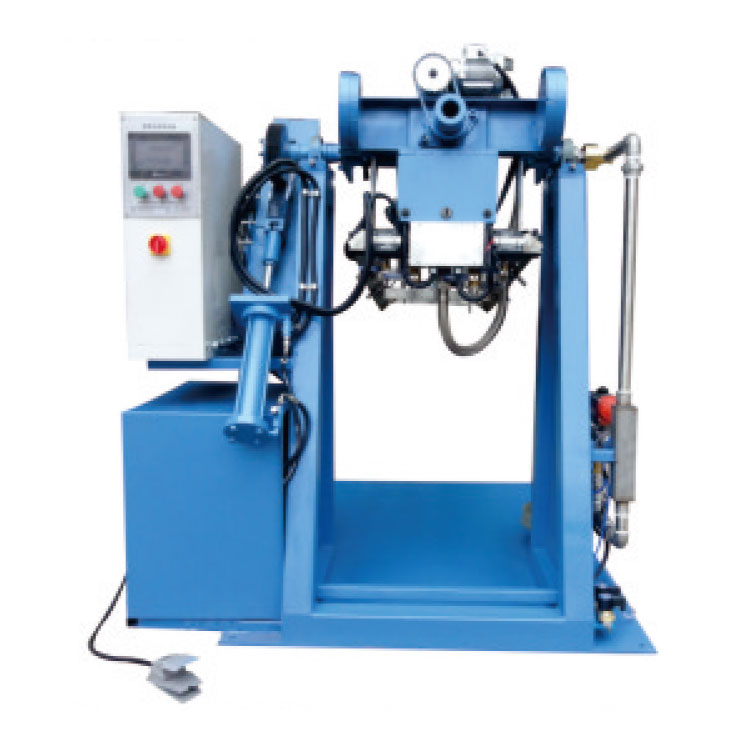

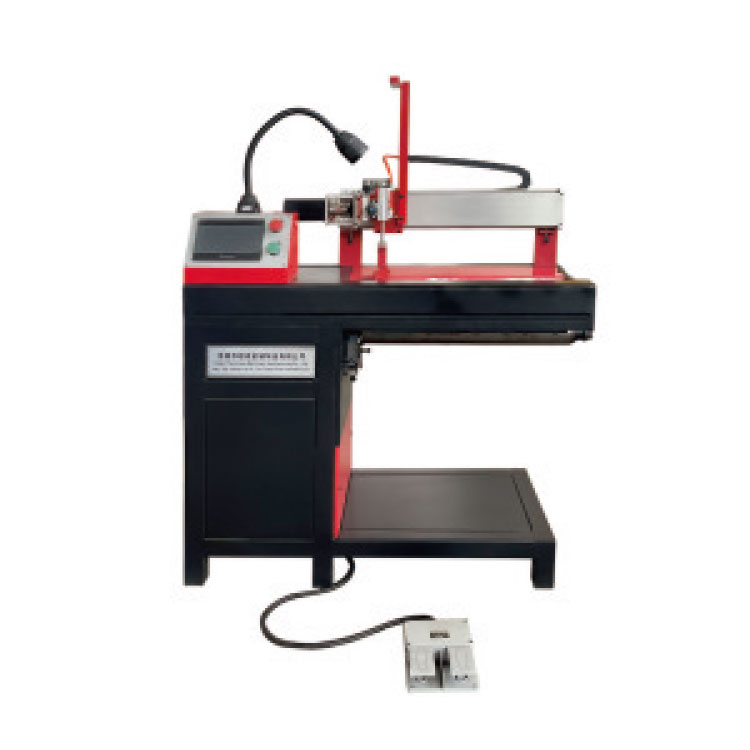

Trolley Fire Extinguisher Welding Machine

Send Inquiry

Trolley Fire Extinguisher Welding Machine Introduction: The equipment is specially designed for welding the upper head and bottom of the trolley fire extinguisher. The employee puts the product on the equipment, presses the foot switch, automatically jacks, automatically tightens, automatically starts welding. The upper head and the lower head are welded at the same time, the welding time is adjustable, and it is automatically released after the welding is completed. The welding frame bed is processed concentricity to ensure stable rotation in the cylinder, the welding seam meets the strength requirements, and the welding yield is high, which meets the requirements of mass production and reducing labor intensity.

Equipment advantages: 1. The equipment adopts stepper motor to drive the equipment to rotate, and the operation is more stable. The conductivity of the equipment is better and the welding effect is good.2.The equipment bed body is processed with high precision, and the welding is more stable and the effect is better.3.The equipment adopts Mitsubishi PLC and Schneider Electric.

Capacity: about 200pcs/8h

Scope of application: 25-50kg

Size: 2230*900*2270MM