- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

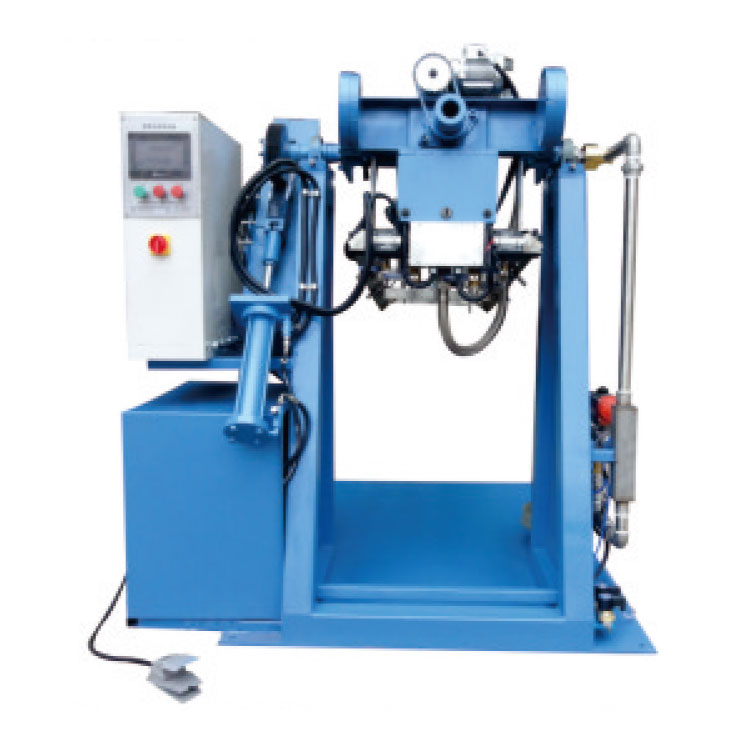

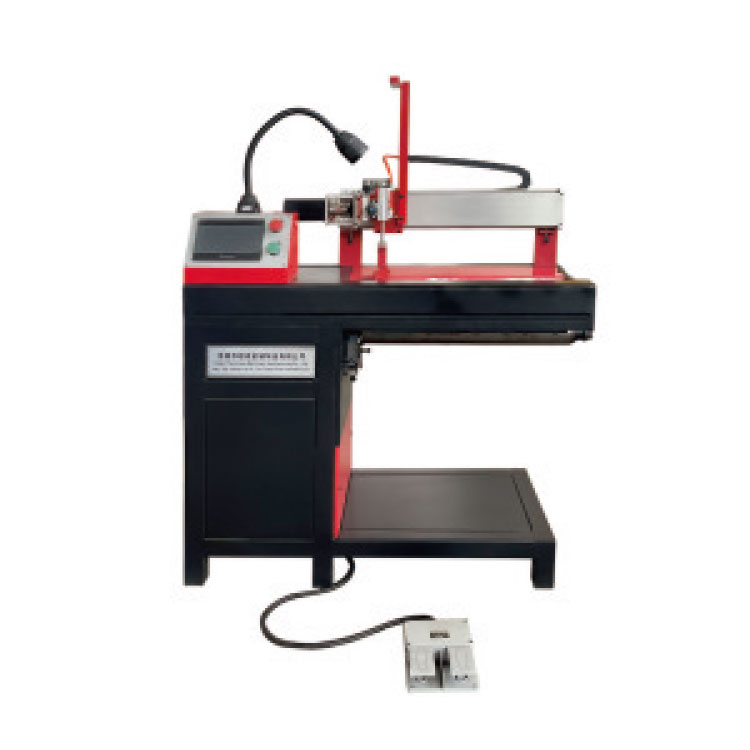

Trolley Fire Extinguisher Straight Seam Welding Machine

Send Inquiry

Trolley Fire Extinguisher Straight Seam Welding Machine introduction: The equipment is specially used for welding the middle seam of the cylinder after rolling. The equipment uses several cylinders to drive the compression cylinder, which is more efficient and stable. The device is also equipped with ejector pins to assist the operator with positioning operations. Press the start button after the cylinder is pressed and fixed, the welding torch is lowered, the servo motor drives the welding torch to start welding laterally, and the welding torch automatically returns to position after the welding is completed. The equipment welding operation is simple, the replacement product adjustment is convenient, the welding is stable, and the

upper and lower parts of the cylinder are convenient.

Equipment advantages: 1. The equipment is controlled by touch screen, and the welding time, welding distance, and welding speed can be set in the touch screen.The equipment adopts servo motor drive, and the welding torch moves more stable and accurately.Equipment parts are quenched and have along service life.

Scope of use: 25-50KG

Equipment capacity: 250-350/8h