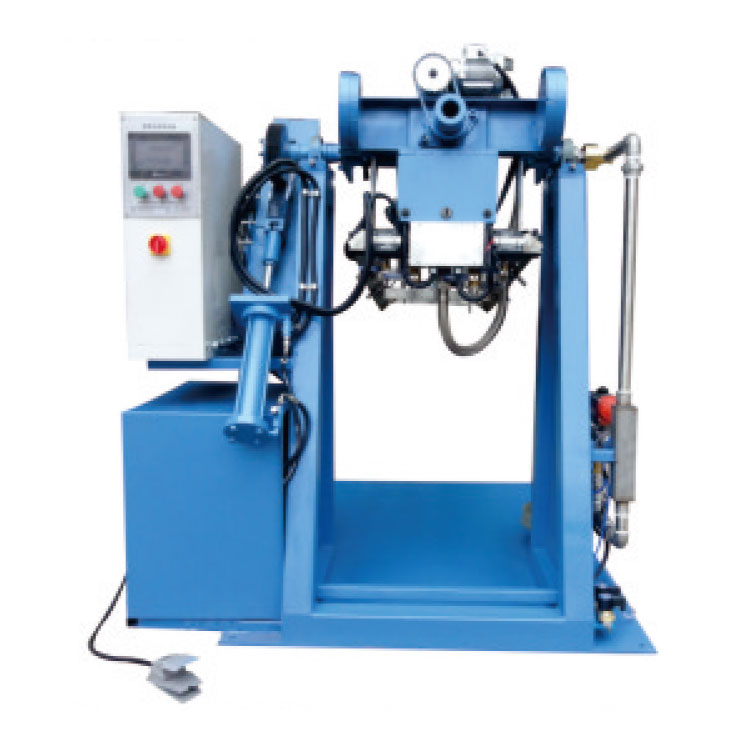

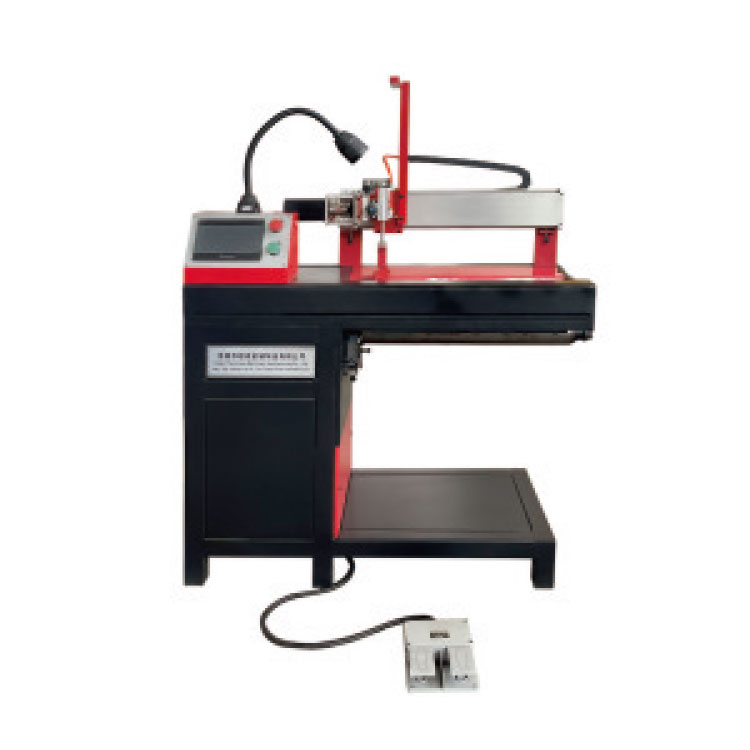

- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

Dry Powder Fire Extinguisher Manufacturing Machine

Dry Powder Fire Extinguisher Manufacturing Machine is complex and require specialized equipment and processes. While I can provide a general overview of the manufacturing process, please note that the specific details may vary depending on the manufacturer and their proprietary methods. Here are the general steps involved in manufacturing a dry powder fire extinguisher:

-

Design and Development: The first step is to design the fire extinguisher, considering factors such as size, capacity, pressure rating, and discharge mechanism. Engineers and designers work together to create the necessary blueprints and specifications.

-

Metal Cylinder Production: The main body of the fire extinguisher is typically made from steel or aluminum. The metal cylinders are produced using sheet metal forming techniques such as deep drawing or spinning. The cylinders are shaped, welded, and tested to ensure they meet safety standards and pressure requirements.

-

Surface Treatment: The cylinders may undergo surface treatment processes like shot blasting, cleaning, and painting to enhance their durability and corrosion resistance.

-

Valve Assembly: The valve assembly is a critical component that controls the flow of the extinguishing agent. It includes a discharge valve, pressure gauge, safety release mechanism, and other necessary fittings. The valves are typically made from brass or stainless steel and are assembled with precision.

-

Dry Powder Filling: The dry powder, which is usually a mixture of chemical agents such as ammonium phosphate or potassium bicarbonate, is prepared separately. The powder is then accurately measured and filled into the fire extinguisher cylinders using automated filling machines. The filling process requires proper control and measurement to ensure the correct quantity of powder is added.

-

Pressurization: Once the cylinders are filled with dry powder, they need to be pressurized. This is typically done by introducing compressed air or an inert gas, such as nitrogen, into the cylinder. The pressure is carefully regulated to ensure the extinguisher functions properly during operation.

-

Final Assembly and Testing: The filled and pressurized cylinders are now ready for final assembly. This involves attaching the valve assembly to the cylinder, performing leak tests, and verifying the overall functionality of the fire extinguisher. Various quality control checks are carried out to ensure that the extinguishers meet safety standards and regulations.

-

Packaging and Distribution: Once the fire extinguishers pass all quality checks, they are packaged appropriately for storage and transportation. Labels and instructions for use are added to the packaging, and the extinguishers are ready to be distributed to customers.

It's important to note that the manufacturing process for fire extinguishers involves strict adherence to safety standards and regulations to ensure the reliability and effectiveness of the products. Manufacturers may also need to comply with specific certifications and testing requirements imposed by regulatory bodies.

- View as