Call Us

+86-13586721191

Email Us

ccmachine@vip.163.com

Products

- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

New Products

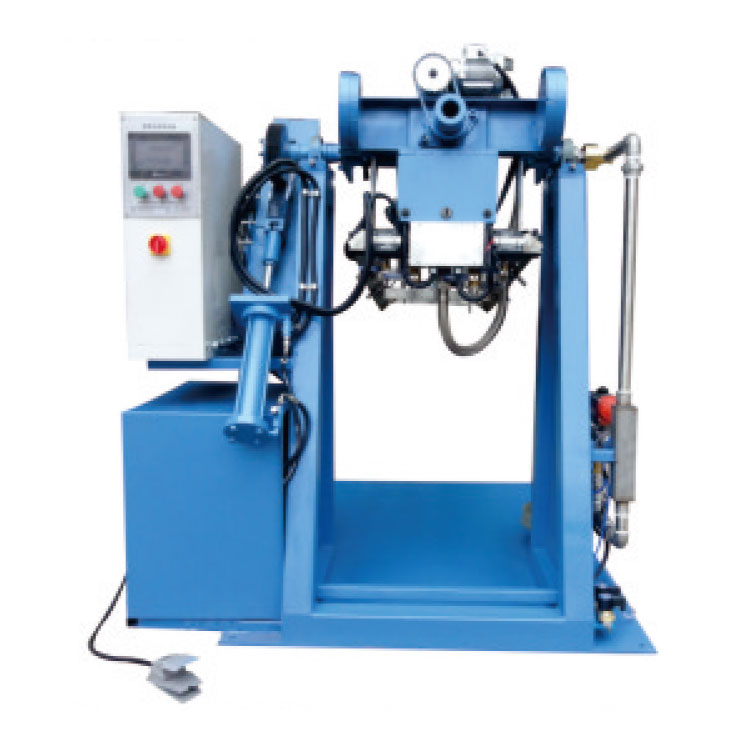

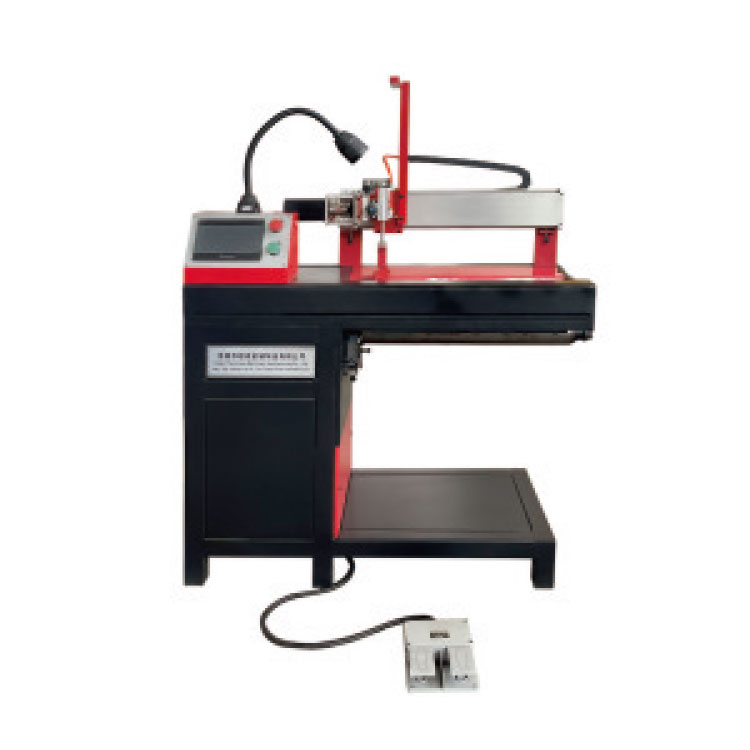

Carbon Dioxide Fire Extinguisher Manufacturing Machine

Chaocheng Carbon Dioxide Fire Extinguisher Manufacturing Machine is specialized equipment designed to automate and optimize the production process. CO2 fire extinguishers are commonly used for suppressing fires involving flammable liquids and electrical equipment. Here is a general overview of the components and processes involved in a CO2 fire extinguisher manufacturing machine:

1. Cylinder Preparation: The first step in manufacturing CO2 fire extinguishers is preparing the cylinders. The machine may handle steel or aluminum cylinders. The cylinders are cleaned, inspected, and undergo surface treatment processes to enhance their corrosion resistance.

2. Valve Assembly: The machine incorporates an automated valve assembly station. It feeds and assembles the necessary valve components onto the cylinders. This can include the discharge valve, pressure gauge, safety release mechanism, and other fittings specific to CO2 fire extinguishers. The machine ensures accurate placement and tight assembly of the valve components.

3. CO2 Filling: The machine includes an automated CO2 filling system. It accurately measures and fills the CO2 gas into the fire extinguisher cylinders. The machine ensures precise filling levels and proper pressurization of the CO2 gas. It may use weight or volume-based systems to control the amount of CO2 filled.

4. Quality Control: Throughout the production process, the machine incorporates quality control mechanisms. It can perform various tests, such as leak testing, pressure testing, and functionality checks, to ensure that the CO2 fire extinguishers meet safety standards and regulatory requirements.

5. Labeling and Packaging: After passing the quality control checks, the extinguishers move through an automated labeling and packaging system. The machine applies labels with product information, safety instructions, and regulatory markings. It also packages the extinguishers appropriately for storage and distribution.

6. Pressure Testing: CO2 fire extinguishers require pressure testing to ensure their integrity and functionality. The machine may include a pressure testing station that subjects the filled extinguishers to specified pressure levels. This test ensures that the cylinders can withstand the pressure and effectively dispense the CO2 gas when needed.

7. Discharge Mechanism Testing: CO2 fire extinguishers have a specific discharge mechanism that releases the CO2 gas upon operation. The machine may include a testing station to verify the proper functioning of the discharge mechanism. This ensures that the extinguisher will effectively dispense the CO2 gas in firefighting situations.

It's important to note that the specific features and capabilities of CO2 fire extinguisher manufacturing machines may vary based on manufacturer requirements. The machines are designed to handle the unique characteristics of CO2 fire extinguishers and ensure efficient and high-quality production. Safety and regulatory compliance are crucial throughout the manufacturing process to ensure the reliability and effectiveness of the CO2 fire extinguishers.

1. Cylinder Preparation: The first step in manufacturing CO2 fire extinguishers is preparing the cylinders. The machine may handle steel or aluminum cylinders. The cylinders are cleaned, inspected, and undergo surface treatment processes to enhance their corrosion resistance.

2. Valve Assembly: The machine incorporates an automated valve assembly station. It feeds and assembles the necessary valve components onto the cylinders. This can include the discharge valve, pressure gauge, safety release mechanism, and other fittings specific to CO2 fire extinguishers. The machine ensures accurate placement and tight assembly of the valve components.

3. CO2 Filling: The machine includes an automated CO2 filling system. It accurately measures and fills the CO2 gas into the fire extinguisher cylinders. The machine ensures precise filling levels and proper pressurization of the CO2 gas. It may use weight or volume-based systems to control the amount of CO2 filled.

4. Quality Control: Throughout the production process, the machine incorporates quality control mechanisms. It can perform various tests, such as leak testing, pressure testing, and functionality checks, to ensure that the CO2 fire extinguishers meet safety standards and regulatory requirements.

5. Labeling and Packaging: After passing the quality control checks, the extinguishers move through an automated labeling and packaging system. The machine applies labels with product information, safety instructions, and regulatory markings. It also packages the extinguishers appropriately for storage and distribution.

6. Pressure Testing: CO2 fire extinguishers require pressure testing to ensure their integrity and functionality. The machine may include a pressure testing station that subjects the filled extinguishers to specified pressure levels. This test ensures that the cylinders can withstand the pressure and effectively dispense the CO2 gas when needed.

7. Discharge Mechanism Testing: CO2 fire extinguishers have a specific discharge mechanism that releases the CO2 gas upon operation. The machine may include a testing station to verify the proper functioning of the discharge mechanism. This ensures that the extinguisher will effectively dispense the CO2 gas in firefighting situations.

It's important to note that the specific features and capabilities of CO2 fire extinguisher manufacturing machines may vary based on manufacturer requirements. The machines are designed to handle the unique characteristics of CO2 fire extinguishers and ensure efficient and high-quality production. Safety and regulatory compliance are crucial throughout the manufacturing process to ensure the reliability and effectiveness of the CO2 fire extinguishers.

- View as

China Carbon Dioxide Fire Extinguisher Manufacturing Machine is one kind of products from CC factory. As the one of leading manufacturers and suppliers in China, we provide advanced and durable Carbon Dioxide Fire Extinguisher Manufacturing Machine made in China from our factory. We sincerely look forward to becoming your reliable long-term business partner!

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy