- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

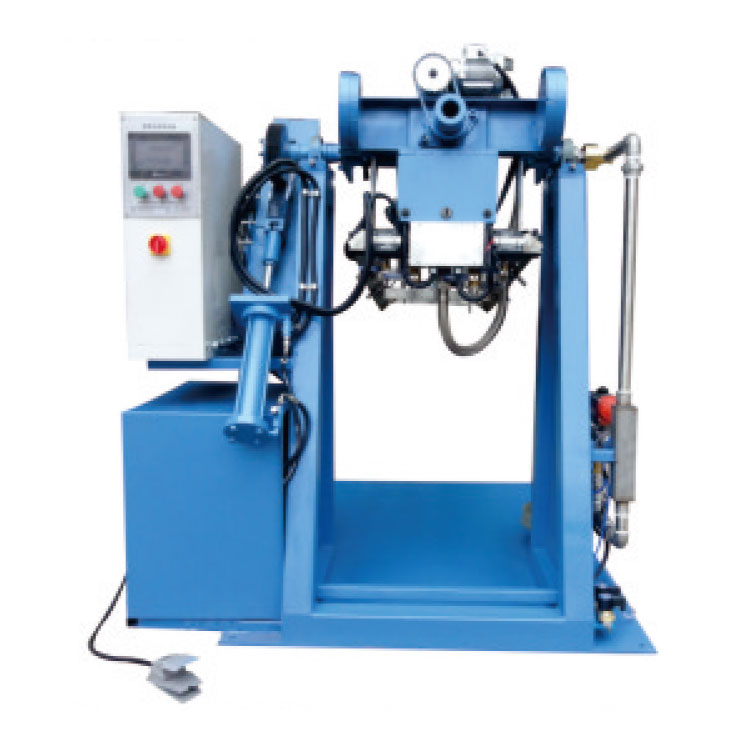

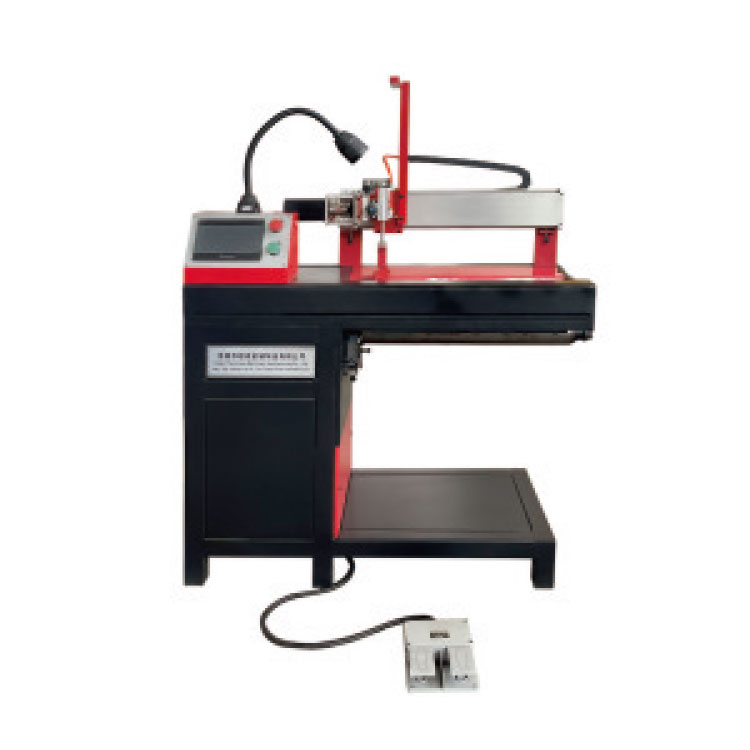

Fire Extinguisher Two Station Internal Coating Machine

Send Inquiry

Fire Extinguisher Two Station Internal Coating Machine Introduction: The equipment is specially designed for anti-corrosion treatment inside water-based fire extinguishers. The equipment is designed with two stations. The device needs to be connected to gas or natural gas. The product is placed on 2 stations in turn, and then press the start switch, ignition, 2 flame strips and flame pipes start to spit fire the flask, remove the oil on the bottle, the purpose of heating is to allow the plastic powder to attach to the bottle. During the heating process, the employees put the funnel containing the plastic powder into the cylinder,and different product specifications correspond to different weights of the plastic powder. During the heating process, the machine will be flipped up and down, the purpose of which is to make the plastic powder more evenly attached to the surface of the cylinder. After heating,it will automatically blow air for cooling. The machine then returns to its origin position and the employee removes the product.

Equipment advantages: 1. The equipment adopts hydraulic system control, good stability, solid and solid.2. Thick coating thickness, usually up to 1-2MM, in line with European Union standards, good product quality.3. The coating efect is good, the surface is smooth, uniform and beautiful.

Equipment scope of application: 3.9L

Equipment capacity: 200-400/8H Size:1500*1150*1500MM