- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

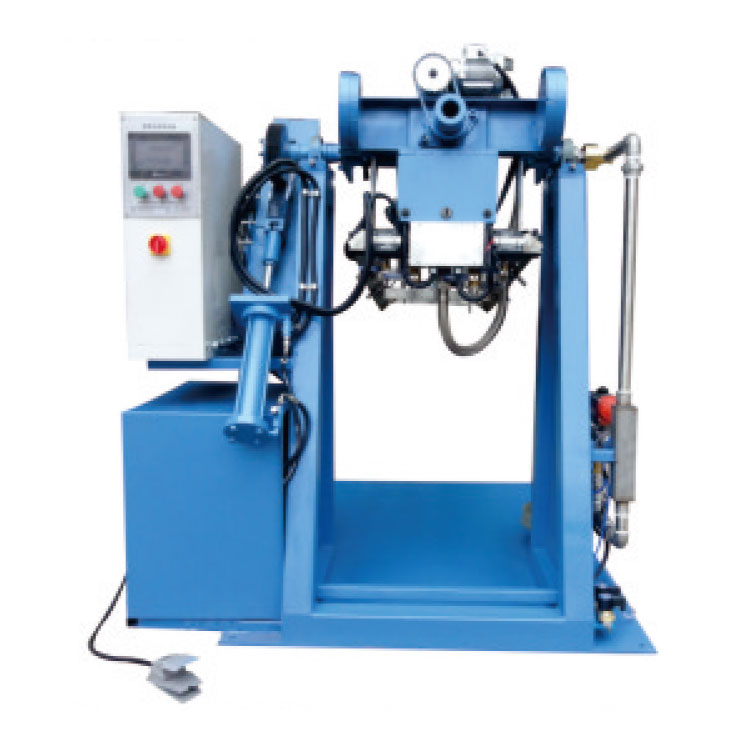

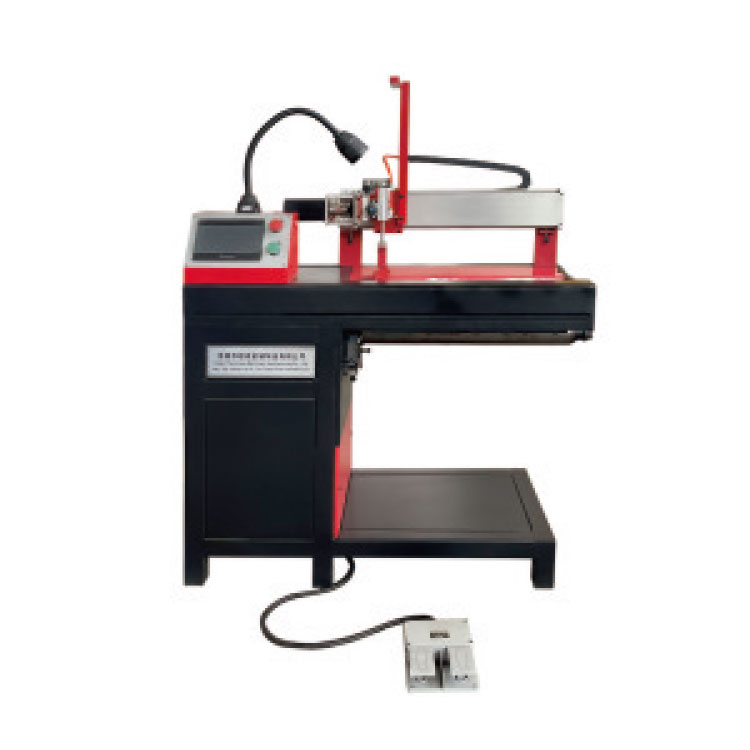

Trolley Fire Extinguisher Two-station Cutting and polishing Machine

Send Inquiry

Trolley Fire Extinguisher Two-station Cutting and polishing Machine introduction: The equipment is specially used for the processing of the upper cover and lower head of the trolley fire extinguisher. Design two workstations. The equipment can be cut separately or pressed edge separately, the purpose of the pressing is to better combine with the cylinder.At the same time, the equipment can also be press edge and cut at the same time, which is a technology of our company.

Equipment operation process: the staff puts the head in the corresponding mold, presses the start button with both hands, the cylinder lowers to fix the product,the spindle drives the product to rotate, the cutter head slowly touches the product under the push of the hydraulic cylinder for cutting, and the cutter head is automatically returned after the cutting time is up. The polishing wheel automatically attaches to the product to polish the product, and after the polishing time is up, the product stops rotating and the employee removes the product.

Equipment advantages: 1. The equipment is welded by thick steel plate, which is very solid and durable.The equipment can not only cut the product, but also automatically polish the product. 3.The equipment adopts hydraulic control, which has large hydraulic strength and stable structure.4.Equipment blades and molds are made of special mold steel material, which has a long service life after quenching treatment.5. The equipment configuration is high, using Japan's Mitsubishi PLC and France's Schneider Electric.