- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

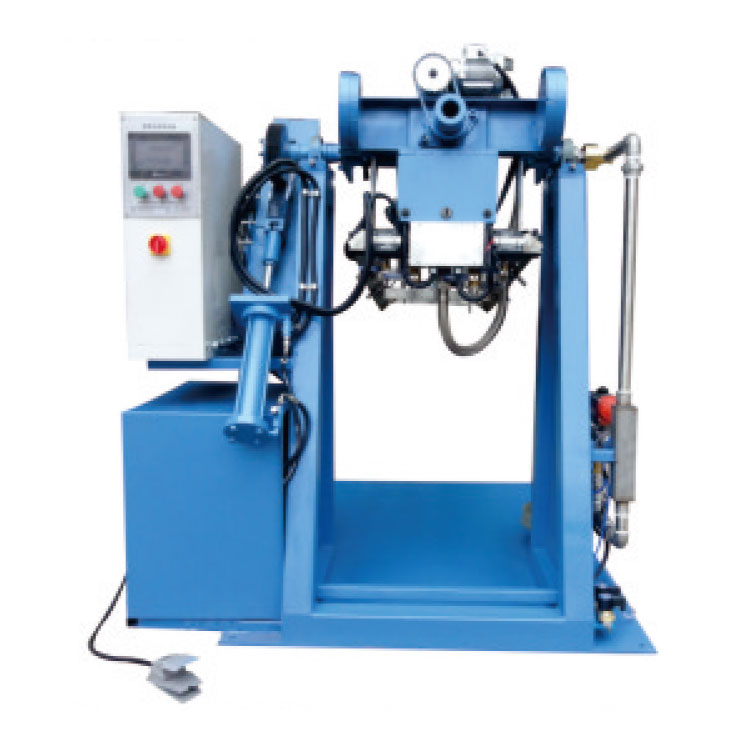

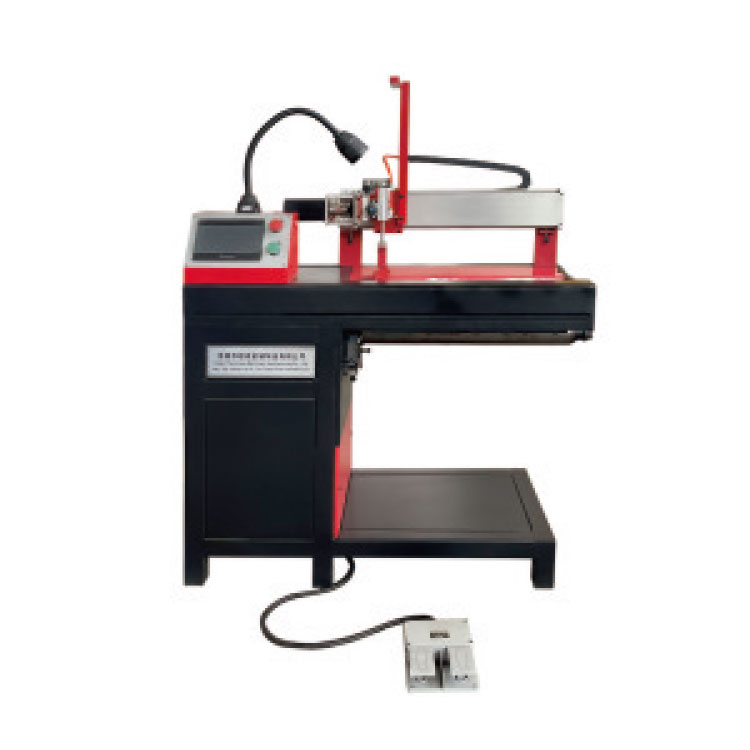

Automatic Water Based Fire Extinguisher

Send Inquiry

Automatic Water Based Fire Extinguisher introduction: T he equipment includes 4 stations of the main engine, a 3.5m stainless steel conveyor belt, and a 1T mixing barrel.Equipment

operation process: the employee puts the four bottles on the conveyor belt in turn, and the four bottles flow forward along the conveyor belt into the equipment working area in turn.The equipment is equipped with a baffle cylinder, when the 4 bottles are into the working position, the conveyor belt stops flowing, the bottle mouth V-shaped bracket fixes the bottle mouth, the water injection head is lowered for water-based filling, and the filling method is natural inflow, so the advantage of filling is to reduce the influence of foam. When the bottle body is about 2/3 full, the water injection head rises to the bottle mouth and continues to fill until the flow meter measures to the set weight, after which the water injection head rises completely, and the V-shaped bracket is returned, and the water stall is forward, to prevent the residual agent on the water injection head from dripping on the bottle body to avoid corrosion of the surface of the product. The conveyor belt automatically starts the product to continue to flow forward, and when the 4 filled products leave the working area, the backstop cylinder automatically moves forward and waits for the new4 bottles to enter the working area and repeats the above operation.

Equipment advantages: 1. The equipment and conveyor belt are made of stainless steel, which is anti-corrosion and durable. Less foam after filing, because the equipment adopts natural inflow method of filling The equipment uses Japanese Mitsubishi PLC and French Schneider Electric 4. The equipment adopts touch screen control system 5.The equipment has a high degree of automation, simple and convenient operation, and meets the mass production.

Scope of application: 3-9L

Capacity: 2000-3000/8H