- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

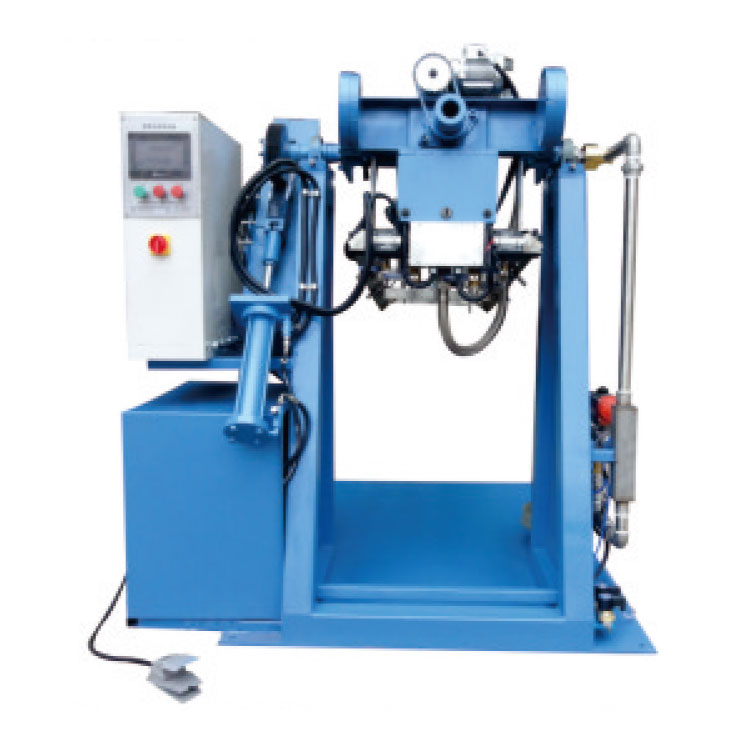

Fire Extinguisher Semi Automatic Cylinder Welding Machine

Send Inquiry

Fire Extinguisher Semi Automatic Cylinder Welding Machine introduction: The equipment is specially designed for fire extinguisher cylinder welding. The employee holds the assembled product by hand and aligns the spindle,presses the foot switch, the spindle presses the bottle mouth, and the tail stock cylinder presses the lower head. Employees can adjust the angle of the welding torch at this time, and then press the start button after the adjustment is completed to start the spindle to start rotating, the welding torch starts to weld the bottle mouth, and the second gun automatically starts welding the upper and lower heads after the bottle mouth welding is completed.After the welding is completed, the welding torch stops and the spindle stops rotating.

Equipment advantages: 1.The welding frame is processed by the concentricity of the machining center to ensure the accuracy of equipment welding concentricity. 2. The welding seam meets the strength requirements, the welding yield is high, it meets the mass production, and the operation is simple and convenient. 3. The equipment adopts Japanese Mitsubishi PLC, French Schneider Electric.4.The machine bed is finished by gantry machining center.

Equipment output: 580-780/8H

Scope of application: 1- 12KG

Machine size: 1630*1020*1850MM