- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

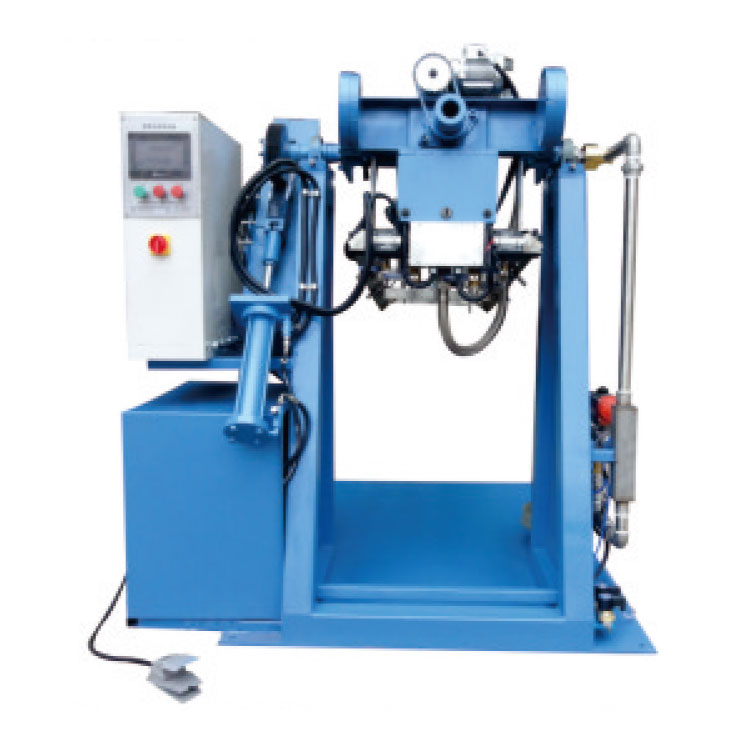

Fire Extinguisher Inside Bottom Welding Machine

Send Inquiry

Fire Extinguisher Inside Bottom Welding Machine introduction: The equipment is specially used for welding the inner bottom after deep drawing cylinder. Scientific equipment design. The bed and rotating spindle are 15 degrees, which ensures that the yield of welding is effectively improved, and the welding strength meets the requirements. The employee puts the assembled product in the corresponding position of the machine, presses start, the welding torch automatically lowers, the spindle drives the product to rotate, and the welding torch starts to start welding. After the welding stops, the welding torch automatically rises and the spindle stops rotating.

Equipment advantages: 1.The equipment is controlled by touch screen, can set any parameters, easy to operate 2. The stepper motor drives the spindle to rotate, with high precision and good stability. 3. The equipment adopts Mitsubishi PLC and French Schneider Electric.