- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

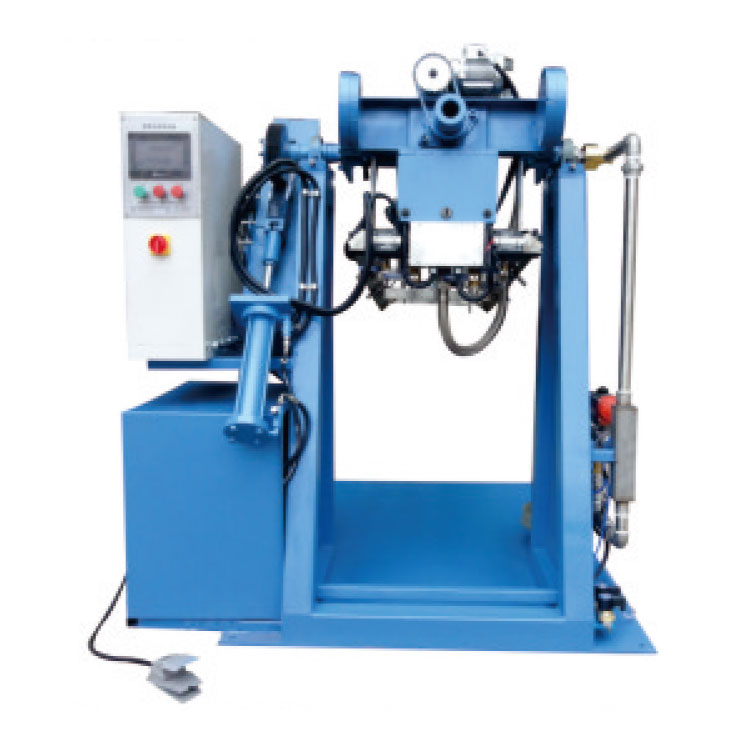

Fire Extinguisher Full Automatic Valve Tighten Machine

Send Inquiry

The Fire Extinguisher Full Automatic Valve Tighten Machine is specially designed for automatic tightening of fire extinguishers valves after dry powder filling. The equipment is equipped with a 4- meter PVC conveyor belt, the staff will complete the pre-screwed fire extinguisher on the conveyor belt (can be placed at will), when the bottle comes to the position of the tightening station,automatically fix the bottle body, laser sensor automatically find the position of the fire extinguisher lifting handle and valve, automatically drop and tighten.The tightening torque is controlled by the servo motor, which can be set arbitrarily in the touch screen, automatically loosened after tightening, the product automatically flows forward, when the product reaches the end of the conveyor belt,the employee tilts the product to the inflatable gun for nitrogen filling. After the inflation is completed, the employee can remove the product.

Equipment advantages: 1. The equipment is welded by steel plate, which is strong and solid, and the bed body is processed by the gantry machining center with high precision.2.The equipment is equipped with Japanese Mitsubishi PLC and French Schneider Electric.3. The equipment is controlled by the touch screen,and the up and down movement is controlled by the motor,and the degree of automation is high.

Equipment capacity: 3000-4000/8H

Use range: 1-12KG