- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

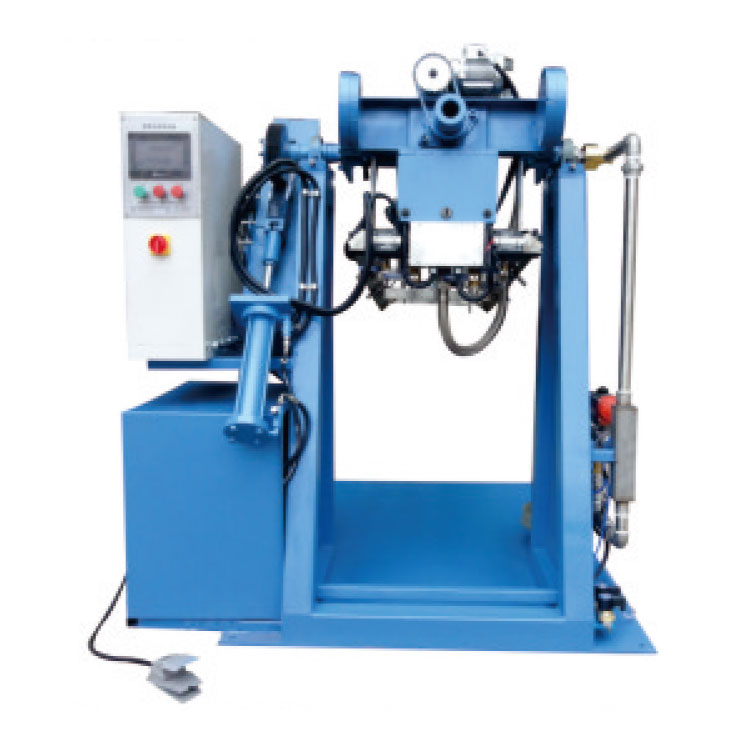

Fire Extinguisher Full Automatic Manipulator Welding Machine

Send Inquiry

Fire Extinguisher Full Automatic Manipulator Welding Machine introduction: The equipment is specially used for fire extinguisher cylinder bottle mouth, upper head, lower head welding equipment. The device is very powerful and can control the stop and start of three guns at will.According to different cylinders included in the stretch cylinder, only when welding the bottle mouth and lower head, the employee can set only two guns to be included in the bottle mouth No. 1 gun and the lower head No.3 gun. If the welding is made by pipe manufacturing machine or rolling machine barrel that needs to be welded in 3 places, then the employee can also set up three starting guns, the bottle mouth gun No.I and the upper head gun No.2 and the lower head gun No.3. During the welding process,the bottle mouth and the upper head and the lower head are welded separately, because the circumference of the bottle mouth and the circumferential diameter of the cylinder are different, so the machine needs to rotate 2 times, the specific process is as follows: the staff will put the assembled fire extinguisher barrel above the automatic feeding manipulator, different specifications are equipped with different manipulator molds can accurately fix the product. The employee presses the start button, the manipulator automatically feeds, the spindle automatically tightens the bottle mouth, the tail stock cylinder automatically tightens the lower head and fixes the product, the manipulator automatically returns, the spindle automatically starts to rotate, and the No. 1 welding torch automatically starts the neck ring. At this point, the next assembled product can continue to be placed on the robot with high efficiency. So one employee can usually operate two or three machines at the same time.After the end of bottle mouth welding,the No.I welding torch will automatically stop, the lower head and upper head welding torch will start welding, and the welding torch will stop after the welding. The spindle stops rotating, the fixed cylinders are all returned,and the product naturally falls on the lower hopper.

Equipment advantages: 1.This equipment has invention patents, is the earliest and most advanced welding fire extinguisher equipment in China since its first birth in 2008.2.One person can operate multiple devices at the same time, and the efficiency is doubled.3.The device is equipped with touch screen operation, the function is very powerful, you can set all the functions you want.4. The equipment adopts Japanese Mitsubishi PLC, French Schneider Electric.5. The equipment is equipped with self-developed manipulator feeding device, the efficiency is doubled, and one employee can operate two to three pieces of equipment at the same time.6. The equipment has good welding effect, beautiful appearance, and the welding strength meets the requirements.7. The equipment adopts stepper motor to drive the spindle to rotate, and the speed is more stable.8. The machine bed is processed by gantry machining center with high precision. The parts are heat treated, durable and wear-resistant.

Equipment output: 700-880/8H

Scope of application: 1KG-4KG、4KG-12KG

Machine size: 1950*1440*1800MM