- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

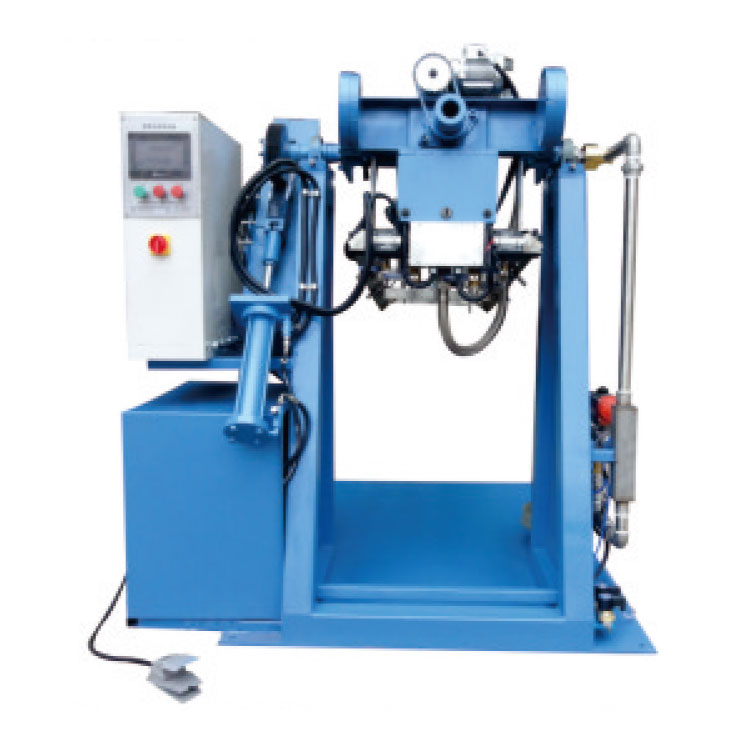

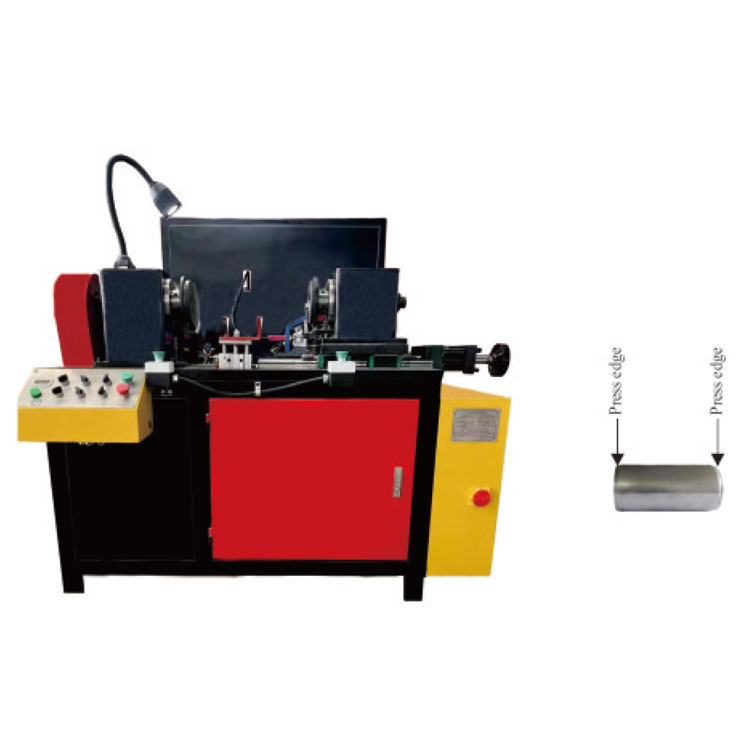

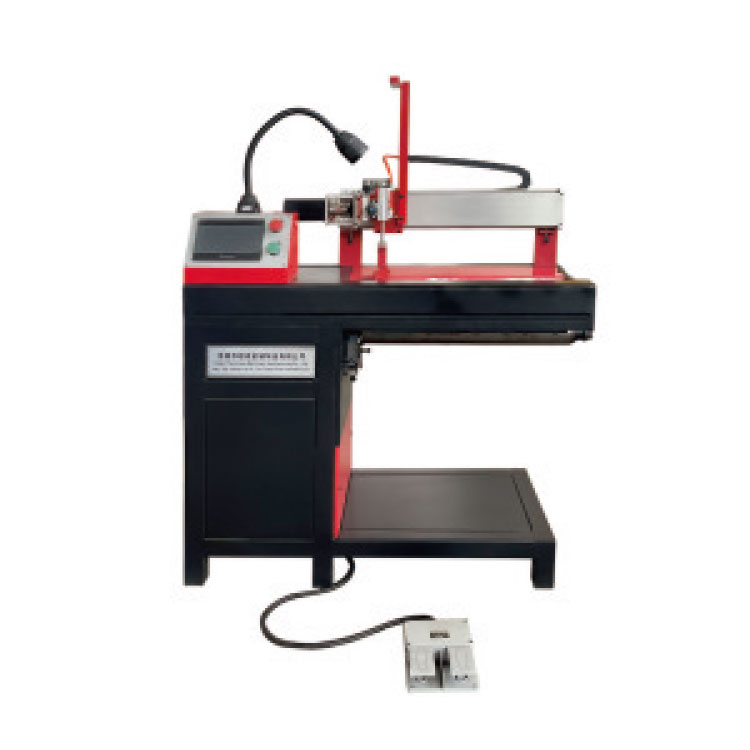

Fire Extinguisher Cylinder Rolling Machine

Send Inquiry

Fire Extinguisher Cylinder Rolling Machine introduction: The equipment is specially used for semi- automatic manufacture of fire extinguisher barrels. A steel plate is processed into a round cylinder. The employee inserts the iron plate into the rotating rubber roller, and the rubber roller and mold begin to rotate and extrude to process the iron plate into a round cylinder. According to different cylinder diameter sizes, different molds need to be replaced.

Equipment advantages: 1. Hydraulic drive, stronger, able to process iron plates below 2.5MM2. The equipment is solid and durable, the bed body is processed, and the operation is simple and convenient.3. The equipment has high precision, and the processed cylinder is very round and has good effect.4. The equipment adopts Mitsubishi PLC and French Schneider Electric.

Equipment output: 3000-4000/8H

Scope of application: 1-12KG

Machine size: 1970°1410°1110MM