- Dry Powder Fire Extinguisher Manufacturing Machine

- Water and Foam Fire Extinguisher Manufacturing Machine

- Carbon Dioxide Fire Extinguisher Manufacturing Machine

- Trolley Fire Extinguisher Manufacturing Machine

- Stainless Steel Fire Extinguisher Production Machine

- Automatic Fire Extinguisher Production Machine

- Water System and Valve Machine

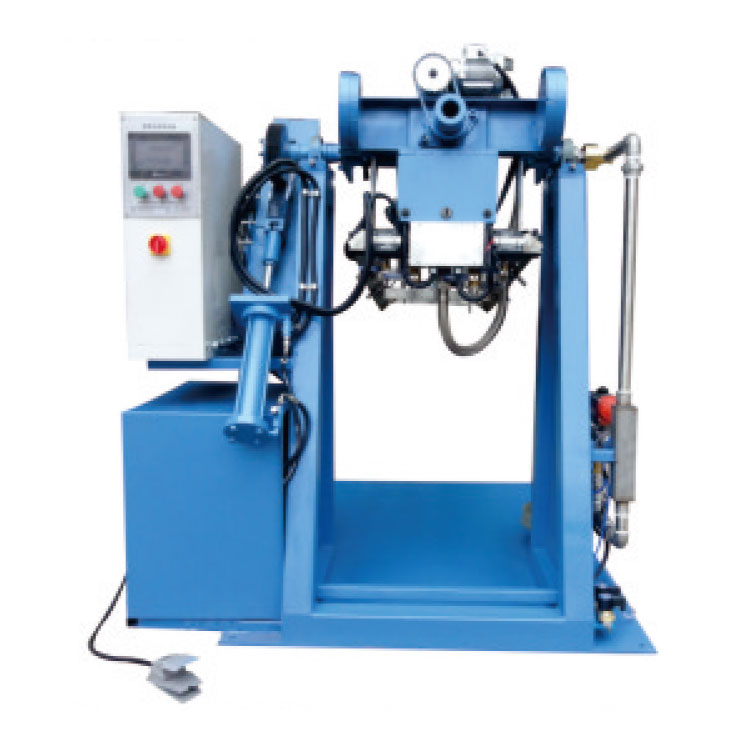

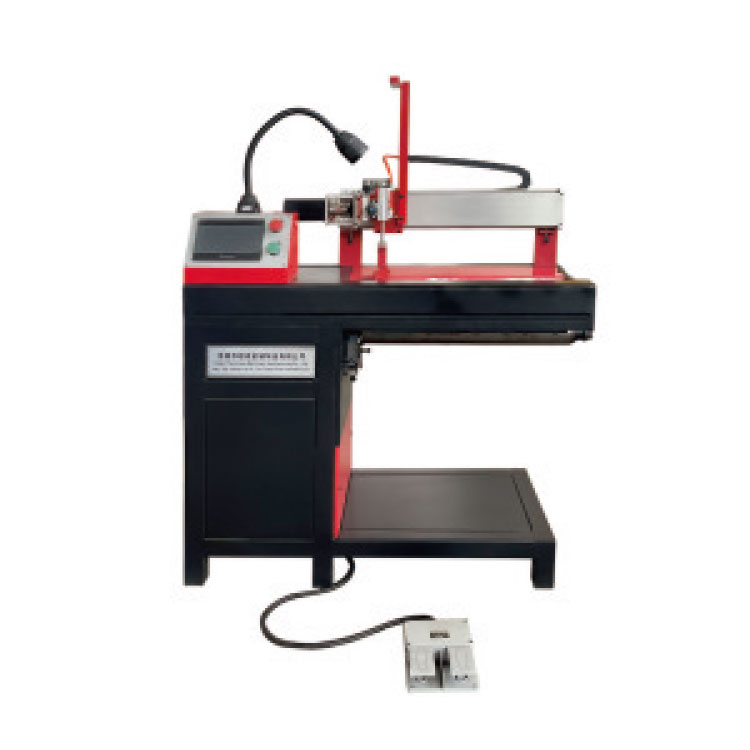

Carbon Dioxide Cylinder Neck Punching Machine

Send Inquiry

Carbon Dioxide Cylinder Neck Punching Machine introduction: The equipment is specially used to punch the steel neck after making the bottom and neck. The equipment adopts hydraulic power, and the bed is strong and durable. The parts are quenched and processed by grinding machines. high production efficiency and good equipment stability. Long service life. Operation process: The employee places the bottle on the equipment. The cylinder automatically tightens the bottom of the cylinder, the power head automatically punches holes, and the cylinder is automatically returned after the drilling is completed, and the employee removes the product.Equipment advantages: 1. Mitsubishi PLC and French Schneider Electric.2.The machine is finished with high precision, and the equipment steel plate is thick and durable.Equipment capacity: 500-700/8h

Adaptation range: maximum drilling φ22

cylinder diameter: φ102-φ152

Length: 250mm-700mm, 700mm-1060mm

Size: 2500*1050*1650mm